Problems with fire engines

| Dokumendiregister | Päästeamet |

| Viit | 6.3-1/85 |

| Registreeritud | 12.11.2025 |

| Sünkroonitud | 18.11.2025 |

| Liik | Väljaminev kiri |

| Funktsioon | 6.3 Välisabiprojektide haldamine |

| Sari | 6.3-1 Välisabiprojektide kirjavahetus, aruandlus (sh riigihanked) ja projektide kuludokumendid |

| Toimik | 6.3-1 |

| Juurdepääsupiirang | Avalik |

| Juurdepääsupiirang | |

| Adressaat | SZCZESNIAK Pojazdy Specjalne Sp. z o.o. |

| Saabumis/saatmisviis | SZCZESNIAK Pojazdy Specjalne Sp. z o.o. |

| Vastutaja | Kristi Orn (halduse valdkond, Õigusosakond) |

| Originaal | Ava uues aknas |

Failid

Digiallkirjad

Allkirjade kehtivust ei ole

kontrollitud.

MARGO KLAOS

PNOEE-37606022759

2025-11-12 14:50:51

Janusz Bitner

SZCZESNIAK Pojazdy Specjalne Sp. z o.o.

[email protected]

Our 12.11.2025 No 6.3-1/85

Problems with fire engines

Dear Janusz Bitner

The Estonian Rescue Services Agency (hereinafter ‘Contracting Authority’), SZCZESNIAK Pojazdy Specjalne Sp. z o.o. (hereinafter ‘Provider’), Scania Eesti AS and Arete Tech OÜ (hereinafter ‘Representative of the Superstructure Manufacturer’) entered into framework agreement No. 6.4-2.1/338ML on 31 August 2023 and signed the underlying public contract No. 6.4-2.1/379ML on 26 September 2023 and the public contract No. 6.4-2.1/442ML on 28 February 2024. Under these public contracts, the Estonian Rescue Services Agency procured 46 (forty-six) fire engines conforming to the technical specifications, complete with rescue equipment.

All fire engines have now been put into service, resulting in the discovery of several problems that we previously pointed out by email. However, we have not yet received definitive responses regarding solutions to these problems and/or timetables. Some of these problems present a serious obstacle to rescue operations and create dangerous situations for rescuers. In this letter, we highlight the most critical and/or recurring problems appearing in multiple fire engines, and we look forward to the Provider’s response on resolving them.

1. Rear sections of fire engines.

1.1. The problem: Rear sections of the fire engines are too low.

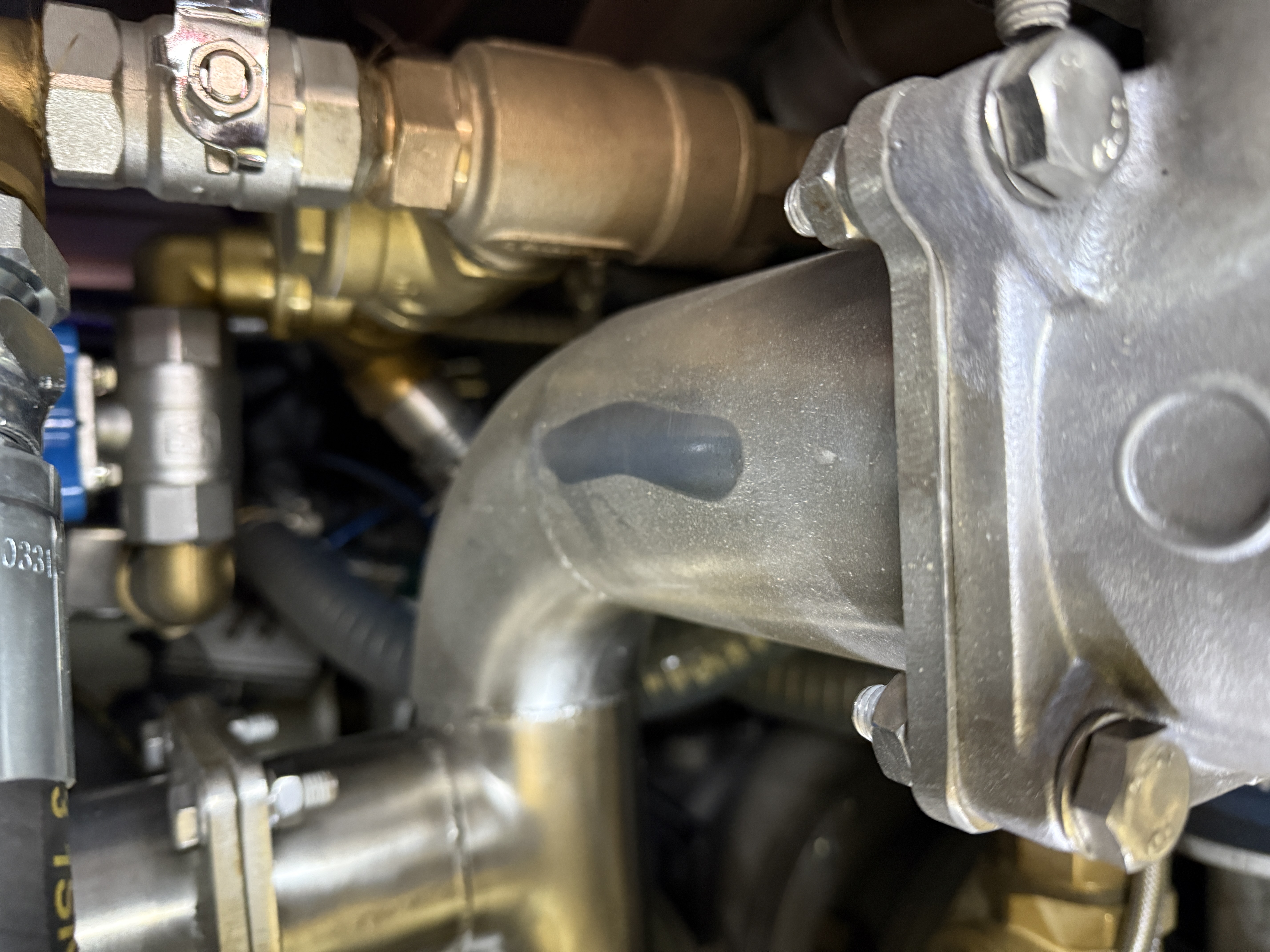

1.2. To illustrate the problem of the low rear sections, we have included a video taken of a fire engine belonging to the Narva Rescue Squad (see Video 1). Images of the slanted superstructure have been appended (see Pictures no 1–3).

1.3. In accordance with the technical specifications of the fire engines as set out in the annex to the framework agreement:

1.3.1. Clause 1.1.1 specifies that the intended use of the fire engines is rescue operations as defined in the Rescue Act – rescuing people and property and carrying out operations to protect the environment in case of fires, natural disasters, catastrophes, accidents, explosions, traffic accidents, and other accidents;

1.3.2. Clause 3.11.3 specifies that the gearbox of the chassis of the fire engine shall withstand difficult road and terrain conditions. If the manufacturer of the chassis offers gearbox software for difficult road and terrain conditions, it must be installed;

1.3.3. Clause 1.1.9 specifies that the fire engine shall comply with the requirements for the fire engine set out in the technical specifications (the fire engine must have a service life of at least 25 (twenty-five) years);

1.3.4. According to clause 1.1.10., the requirements of the technical specifications (except the requirements for the height of the fire engine) apply to a fully equipped fire engine with a full load (maximum authorised weight).

1.4. Based on the cited clauses, the fire engines should be suitable for use on terrain and in difficult conditions. Today, it is not possible to do this safely and without causing damage to the fire engine. Fire engines should maintain their properties and remain technically compliant for 25 years. Seeing that the low rear sections and slanted superstructures are already causing problems, it does not seem plausible that the fire engines could have a service life of 25 years.

1.5. The rear section of the superstructure of the fire engines is visibly lower than the front section. In addition, it can already be seen in some fire engines that the left side of the superstructure is lower than the right side. This difference is most notable on the fire engine with the registration number 742 DDV. The left side of the superstructure of this fire engine is 5–6 cm lower than the right side. This unequal weight distribution has a strong negative impact on the manoeuvrability of the fire engine and puts the lives of our rescuers at risk when responding to emergencies.

1.6. The rear section of the fire engine superstructure extends well beyond the rear axle, and there are also parts sticking out under the rear section of the fire engine that can easily get caught or damaged by surface irregularities. For example, various parts touch the road surface when a fire engine passes over a speed bump in the city, rendering it impossible to open the lower parts of the compartments (see Picture 4). Mainly, this affects compartments 3 and 6. These compartments are used for storing fire-fighting equipment. This creates a major risk that the crew cannot commence rescue operations (fire-fighting) immediately after arriving at a critical event site and they will have to wait for the next crew in order to have access to the necessary equipment.

1.7. According to sub-clause 5.1.16.1 of the technical specifications, disregarding the specified approach and departure angles was permitted where necessary. However, this cannot result in a situation where the fire engine cannot be used for its intended purpose (as stated in clause 1.1.1 of the technical specifications) or the use of the fire engine becomes unsafe, prevents rescue operations or causes damage to the fire engine itself. According to the assessment of the Contracting Authority, this problem is not the result of disregarding the specified approach and departure angles as permitted in sub-clause 5.1.16.1 of the technical specifications.

1.8. Based on the above, clause 1.1.1 of the technical specifications has not been fulfilled, i.e., the fire engine cannot be used without causing damage to it when rescuing people and property and carrying out operations to protect the environment in case of fires, natural disasters, catastrophes, accidents, explosions, traffic accidents, and other accidents.

1.9. We expect the Provider to:

1.9.1. remedy the non-conformity under the warranty;

1.9.2. raise the rear sections of the fire engines to remedy the non-conformity;

1.9.3. propose a solution to address the problem, accompanied by a description;

1.9.4. submit a timetable for resolving the problem.

2. Dust in the compartments of the superstructure.

2.1. The problem: Dust gets into the compartments of the superstructure while driving.

2.2. Images have been appended to illustrate the situation (see Pictures no 5–7).

2.3. Clause 5.1.3 of the technical specifications: Compartments of the superstructure must be maintained under positive pressure to prevent dust ingress.

2.4. This requirement was included in the technical specifications because it is clearly impractical to build a fully sealed superstructure and using positive pressure is an easier solution for preventing excess dust from entering the compartments of the superstructure.

2.5. We have noticed that a significant amount of dust gets into all compartments of the superstructure when driving on gravel roads. This results in a significant increase in the amount of maintenance work for rescuers after an event and has a detrimental effect on many elements of the equipment.

2.6. The dust ingress in the compartments also raises the question whether this design makes the compartments susceptible to freezing when the outside temperature drops significantly below 0 degrees. Section 2.2 of the technical specifications sets out the conditions under which the fire engine must be usable without failure. This includes the requirement that the heating system of the superstructure must ensure a temperature of at least +1 °C in the closed equipment compartments when the fire engine is stationary or operated at ambient temperatures down to -30 C.

2.7. If large amounts of dust can enter the compartments, it is hard to believe that no cold gets into the compartments and no freezing takes place at -30°C. Cold-cutting units and their components are particularly susceptible to low temperatures.

2.8. According to the assessment of the Contracting Authority, the problem may have been caused by unsealed openings in the rear wall of compartment 7 and an incorrectly designed positive pressure system. To illustrate the problem, we append a video of a test with a vehicle using paraffin smoke (see Video 2).

2.9. We expect the Provider to:

2.9.1. remedy the non-conformity under the warranty;

2.9.2. propose a solution to the problem of dust in the compartments (description of the solution and timetable);

2.9.3. confirm that the current fire engine design ensures compliance with the requirements of section 2.2 of the technical specifications, i.e., that the heating system of the superstructure ensures a temperature of at least +1°C in the closed equipment compartments when the fire engine is stationary or operated at ambient temperatures down to -30°C.

3. Rear parking sensor malfunctions.

3.1. The problem: rear parking sensors generate false alarms.

3.2. During the acceptance of the fire engines, malfunctions of the parking sensors were detected and the Contracting Authority notified the Provider of the problem by email. The problem was then seemingly resolved, but the implemented solution does not work, as the vehicles in service continue to exhibit the same issues. The problems do not occur every time, but they do in 7 out of 10 instances.

3.3. We expect the Provider to:

3.3.1. remedy the non-conformity under the warranty;

3.3.2. submit a description of the solution and a timetable.

4. Winches – wired and remote control panel.

4.1. The problem: Winches are prone to unintentional activation.

4.2. On acceptance of the prototype of the fire engine, the Provider informed us that a problem has been observed in the past with winches fitted on the main vehicle, where other devices using similar wavelengths (such as remote gate control) can cause spontaneous activation of the winch. The Provider added that the issue can be resolved by using the electronics system of another manufacturer and promised to replace the system on all fire engines.

4.3. The Contracting Authority and the Provider agreed that the electronics systems of all winches will be replaced as soon as the necessary spare parts are obtained.

4.4. After the acceptance of the fire engines by the Contracting Authority, the Provider has started to claim that the problem described does not actually exist and that the electronics systems will not be replaced.

4.5. The Contracting Authority has already experienced this situation once. A respective video is appended (see Video 3). During one event, the winch activated completely unintentionally.

4.6. Spontaneous activation of the winch during a rescue event can hamper rescue operations and create a safety hazard for rescuers.

4.7. We expect the Provider to:

4.7.1. resolve the problem that was identified by the Provider themselves;

4.7.2. submit a description of the solution and a timetable.

5. Cobra fans.

5.1. The problem: In sunny or hot weather, the fans of the cold-cutting unit stay on for long periods, shortening the life of the unit, draining the battery of the fire engine, and causing additional noise.

5.2. The Contracting Authority and the Representative of the Superstructure Manufacturer have agreed that the problem will be resolved under the warranty and the Representative of the Superstructure Manufacturer will submit to the Contracting Authority by 10 October 2025 a vehicle-by-vehicle timetable for the elimination of the deficiencies.

5.3. We expect the Provider to:

5.3.1. Confirm that the work will be carried out under the warranty according to the timetable proposed by the Representative of the Superstructure Manufacturer.

We ask SZCZESNIAK Pojazdy Specjalne Sp. z o.o. to provide written responses to each point. Please prepare your responses individually for each point. Please note that the deadlines for the performance of works under the warranty are set out in section 2.2. of Annex 2 to the framework agreement.

Your feedback is requested as soon as possible, and by 26 November 2025 at the latest.

Yours faithfully,

(digitally signed)

Margo Klaos

Director-General

Kristi Orn

+372 58857634

[email protected]

Janusz Bitner

SZCZESNIAK Pojazdy Specjalne Sp. z o.o.

[email protected]

Our 12.11.2025 No 6.3-1/85

Problems with fire engines

Dear Janusz Bitner

The Estonian Rescue Services Agency (hereinafter ‘Contracting Authority’), SZCZESNIAK Pojazdy Specjalne Sp. z o.o. (hereinafter ‘Provider’), Scania Eesti AS and Arete Tech OÜ (hereinafter ‘Representative of the Superstructure Manufacturer’) entered into framework agreement No. 6.4-2.1/338ML on 31 August 2023 and signed the underlying public contract No. 6.4-2.1/379ML on 26 September 2023 and the public contract No. 6.4-2.1/442ML on 28 February 2024. Under these public contracts, the Estonian Rescue Services Agency procured 46 (forty-six) fire engines conforming to the technical specifications, complete with rescue equipment.

All fire engines have now been put into service, resulting in the discovery of several problems that we previously pointed out by email. However, we have not yet received definitive responses regarding solutions to these problems and/or timetables. Some of these problems present a serious obstacle to rescue operations and create dangerous situations for rescuers. In this letter, we highlight the most critical and/or recurring problems appearing in multiple fire engines, and we look forward to the Provider’s response on resolving them.

1. Rear sections of fire engines.

1.1. The problem: Rear sections of the fire engines are too low.

1.2. To illustrate the problem of the low rear sections, we have included a video taken of a fire engine belonging to the Narva Rescue Squad (see Video 1). Images of the slanted superstructure have been appended (see Pictures no 1–3).

1.3. In accordance with the technical specifications of the fire engines as set out in the annex to the framework agreement:

1.3.1. Clause 1.1.1 specifies that the intended use of the fire engines is rescue operations as defined in the Rescue Act – rescuing people and property and carrying out operations to protect the environment in case of fires, natural disasters, catastrophes, accidents, explosions, traffic accidents, and other accidents;

1.3.2. Clause 3.11.3 specifies that the gearbox of the chassis of the fire engine shall withstand difficult road and terrain conditions. If the manufacturer of the chassis offers gearbox software for difficult road and terrain conditions, it must be installed;

1.3.3. Clause 1.1.9 specifies that the fire engine shall comply with the requirements for the fire engine set out in the technical specifications (the fire engine must have a service life of at least 25 (twenty-five) years);

1.3.4. According to clause 1.1.10., the requirements of the technical specifications (except the requirements for the height of the fire engine) apply to a fully equipped fire engine with a full load (maximum authorised weight).

1.4. Based on the cited clauses, the fire engines should be suitable for use on terrain and in difficult conditions. Today, it is not possible to do this safely and without causing damage to the fire engine. Fire engines should maintain their properties and remain technically compliant for 25 years. Seeing that the low rear sections and slanted superstructures are already causing problems, it does not seem plausible that the fire engines could have a service life of 25 years.

1.5. The rear section of the superstructure of the fire engines is visibly lower than the front section. In addition, it can already be seen in some fire engines that the left side of the superstructure is lower than the right side. This difference is most notable on the fire engine with the registration number 742 DDV. The left side of the superstructure of this fire engine is 5–6 cm lower than the right side. This unequal weight distribution has a strong negative impact on the manoeuvrability of the fire engine and puts the lives of our rescuers at risk when responding to emergencies.

1.6. The rear section of the fire engine superstructure extends well beyond the rear axle, and there are also parts sticking out under the rear section of the fire engine that can easily get caught or damaged by surface irregularities. For example, various parts touch the road surface when a fire engine passes over a speed bump in the city, rendering it impossible to open the lower parts of the compartments (see Picture 4). Mainly, this affects compartments 3 and 6. These compartments are used for storing fire-fighting equipment. This creates a major risk that the crew cannot commence rescue operations (fire-fighting) immediately after arriving at a critical event site and they will have to wait for the next crew in order to have access to the necessary equipment.

1.7. According to sub-clause 5.1.16.1 of the technical specifications, disregarding the specified approach and departure angles was permitted where necessary. However, this cannot result in a situation where the fire engine cannot be used for its intended purpose (as stated in clause 1.1.1 of the technical specifications) or the use of the fire engine becomes unsafe, prevents rescue operations or causes damage to the fire engine itself. According to the assessment of the Contracting Authority, this problem is not the result of disregarding the specified approach and departure angles as permitted in sub-clause 5.1.16.1 of the technical specifications.

1.8. Based on the above, clause 1.1.1 of the technical specifications has not been fulfilled, i.e., the fire engine cannot be used without causing damage to it when rescuing people and property and carrying out operations to protect the environment in case of fires, natural disasters, catastrophes, accidents, explosions, traffic accidents, and other accidents.

1.9. We expect the Provider to:

1.9.1. remedy the non-conformity under the warranty;

1.9.2. raise the rear sections of the fire engines to remedy the non-conformity;

1.9.3. propose a solution to address the problem, accompanied by a description;

1.9.4. submit a timetable for resolving the problem.

2. Dust in the compartments of the superstructure.

2.1. The problem: Dust gets into the compartments of the superstructure while driving.

2.2. Images have been appended to illustrate the situation (see Pictures no 5–7).

2.3. Clause 5.1.3 of the technical specifications: Compartments of the superstructure must be maintained under positive pressure to prevent dust ingress.

2.4. This requirement was included in the technical specifications because it is clearly impractical to build a fully sealed superstructure and using positive pressure is an easier solution for preventing excess dust from entering the compartments of the superstructure.

2.5. We have noticed that a significant amount of dust gets into all compartments of the superstructure when driving on gravel roads. This results in a significant increase in the amount of maintenance work for rescuers after an event and has a detrimental effect on many elements of the equipment.

2.6. The dust ingress in the compartments also raises the question whether this design makes the compartments susceptible to freezing when the outside temperature drops significantly below 0 degrees. Section 2.2 of the technical specifications sets out the conditions under which the fire engine must be usable without failure. This includes the requirement that the heating system of the superstructure must ensure a temperature of at least +1 °C in the closed equipment compartments when the fire engine is stationary or operated at ambient temperatures down to -30 C.

2.7. If large amounts of dust can enter the compartments, it is hard to believe that no cold gets into the compartments and no freezing takes place at -30°C. Cold-cutting units and their components are particularly susceptible to low temperatures.

2.8. According to the assessment of the Contracting Authority, the problem may have been caused by unsealed openings in the rear wall of compartment 7 and an incorrectly designed positive pressure system. To illustrate the problem, we append a video of a test with a vehicle using paraffin smoke (see Video 2).

2.9. We expect the Provider to:

2.9.1. remedy the non-conformity under the warranty;

2.9.2. propose a solution to the problem of dust in the compartments (description of the solution and timetable);

2.9.3. confirm that the current fire engine design ensures compliance with the requirements of section 2.2 of the technical specifications, i.e., that the heating system of the superstructure ensures a temperature of at least +1°C in the closed equipment compartments when the fire engine is stationary or operated at ambient temperatures down to -30°C.

3. Rear parking sensor malfunctions.

3.1. The problem: rear parking sensors generate false alarms.

3.2. During the acceptance of the fire engines, malfunctions of the parking sensors were detected and the Contracting Authority notified the Provider of the problem by email. The problem was then seemingly resolved, but the implemented solution does not work, as the vehicles in service continue to exhibit the same issues. The problems do not occur every time, but they do in 7 out of 10 instances.

3.3. We expect the Provider to:

3.3.1. remedy the non-conformity under the warranty;

3.3.2. submit a description of the solution and a timetable.

4. Winches – wired and remote control panel.

4.1. The problem: Winches are prone to unintentional activation.

4.2. On acceptance of the prototype of the fire engine, the Provider informed us that a problem has been observed in the past with winches fitted on the main vehicle, where other devices using similar wavelengths (such as remote gate control) can cause spontaneous activation of the winch. The Provider added that the issue can be resolved by using the electronics system of another manufacturer and promised to replace the system on all fire engines.

4.3. The Contracting Authority and the Provider agreed that the electronics systems of all winches will be replaced as soon as the necessary spare parts are obtained.

4.4. After the acceptance of the fire engines by the Contracting Authority, the Provider has started to claim that the problem described does not actually exist and that the electronics systems will not be replaced.

4.5. The Contracting Authority has already experienced this situation once. A respective video is appended (see Video 3). During one event, the winch activated completely unintentionally.

4.6. Spontaneous activation of the winch during a rescue event can hamper rescue operations and create a safety hazard for rescuers.

4.7. We expect the Provider to:

4.7.1. resolve the problem that was identified by the Provider themselves;

4.7.2. submit a description of the solution and a timetable.

5. Cobra fans.

5.1. The problem: In sunny or hot weather, the fans of the cold-cutting unit stay on for long periods, shortening the life of the unit, draining the battery of the fire engine, and causing additional noise.

5.2. The Contracting Authority and the Representative of the Superstructure Manufacturer have agreed that the problem will be resolved under the warranty and the Representative of the Superstructure Manufacturer will submit to the Contracting Authority by 10 October 2025 a vehicle-by-vehicle timetable for the elimination of the deficiencies.

5.3. We expect the Provider to:

5.3.1. Confirm that the work will be carried out under the warranty according to the timetable proposed by the Representative of the Superstructure Manufacturer.

We ask SZCZESNIAK Pojazdy Specjalne Sp. z o.o. to provide written responses to each point. Please prepare your responses individually for each point. Please note that the deadlines for the performance of works under the warranty are set out in section 2.2. of Annex 2 to the framework agreement.

Your feedback is requested as soon as possible, and by 26 November 2025 at the latest.

Yours faithfully,

(digitally signed)

Margo Klaos

Director-General

Kristi Orn

+372 58857634

[email protected]

Seosed

| Nimi | K.p. | Δ | Viit | Tüüp | Org | Osapooled |

|---|---|---|---|---|---|---|

| Hankelepingu nr 6.4-2.1/35ML mittenõuetekohane täitmine | 12.01.2026 | 1 | 1.2-2.1/7149-4 🔒 | Väljaminev kiri | paa | MDSC Systems OÜ |

| Hankelepingu nr 6.4-2.1/35ML mittenõuetekohane täitmine | 11.12.2025 | 1 | 1.2-2.1/7149-3 🔒 | Sissetulev kiri | paa | MDSC Systems OÜ |

| Hankelepingu nr 6.4-2.1/35ML mittenõuetekohane täitmine | 01.12.2025 | 2 | 1.2-2.1/7149-2 🔒 | Väljaminev kiri | paa | MDSC Systems OÜ |

| Ettepanek staabiautode tarnetähtaja pikendamiseks | 28.11.2025 | 3 | 1.2-2.1/7149-1 🔒 | Sissetulev kiri | paa | MDSC Systems OÜ |

| Letter about issues regarding our trucks (2850-2895) | 20.11.2025 | 1 | 6.3-1/85 🔒 | Sissetulev kiri | paa | SZCZĘŚNIAK Pojazdy Specjalne Sp. z o.o. |

| Hankeleping nr 6.4-2.1_35ML_lisa 4 | 23.10.2025 | 5 | 6.4-2.1/259ML | Leping | paa | |

| Hankelepingu nr 6.4-2.1/379 lisa 5 | 17.06.2025 | 1 | 6.4-2.1/187ML | Leping | paa | |

| Hankelepingu nr 6.4-2.1/442 lisa 3 | 17.06.2025 | 1 | 6.4-2.1/188ML | Leping | paa | |

| Maksetaotlus | 02.05.2025 | 4 | 6.3-1//39 | Väljaminev kiri | paa | SA Keskkonnainvesteeringute Keskus |

| Hankeleping raamlepingu alusel | 30.01.2024 | 57 | 6.4-2.1/35ML | Leping | paa | |

| Raamleping | 23.01.2024 | 64 | 6.4-2.1/25ML | Leping | paa | |

| Projekti aruanne nr 1 | 08.01.2024 | 79 | 6.3-1/11-2 | Väljaminev kiri | paa | SA Keskkonnainvesteeringute Keskus |

| Raamlepingu nr 6.4-2.1/338ML alusel sõlmitav hankeleping | 29.11.2023 | 119 | 6.4-2.1/442ML | Leping | paa | |

| Hankelepingu nr 6.4-2.1/379ML lisa 4 | 26.10.2023 | 153 | 6.4-2.1/412ML | Leping | paa | |

| Raamlepingu nr 6.4-2.1/338ML alusel sõlmitav hankeleping | 14.09.2023 | 195 | 6.4-2.1/379ML | Leping | paa | |

| Päästesõidukite ja päästevarustuse soetamine, IT-lahenduse väljatöötamine ning toimepidevuse ja kriisideks valmisoleku suurendamine | 17.08.2023 | 223 | 6.3-1/11-1 | Sissetulev kiri | paa | SA Keskkonnainvesteeringute Keskus |

| Põhiautode ostmine koos garantiiaegsete korraliste hoolduste ja erakorraliste remonttööde tellimise ning varuosade ostmisega | 09.08.2023 | 231 | 6.4-2.1/338ML | Leping | paa | |

| Helikopteri konteiner-basseini ostmise hankeleping | 08.05.2023 | 324 | 6.3-3/147VL | Leping | paa | |

| Toetuse andmise tingimused päästevõimekuse suurendamise toetamiseks | 08.05.2023 | 324 | 6.3-1/3-1 | Sissetulev kiri | paa | Siseministeerium |